The Project Gutenberg EBook of Scientific American Supplement, No. 623, December 10, 1887, by Various This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.net Title: Scientific American Supplement, No. 623, December 10, 1887 Author: Various Release Date: July 12, 2005 [EBook #16270] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK SCIENTIFIC AMERICAN *** Produced by Juliet Sutherland and the Online Distributed Proofreading Team at www.pgdp.net.

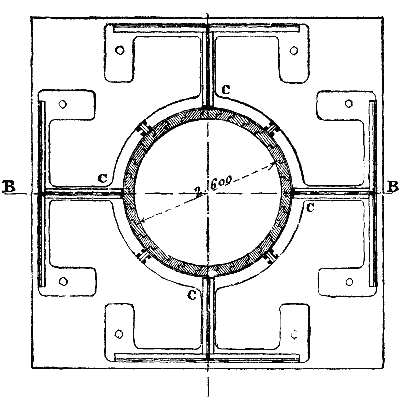

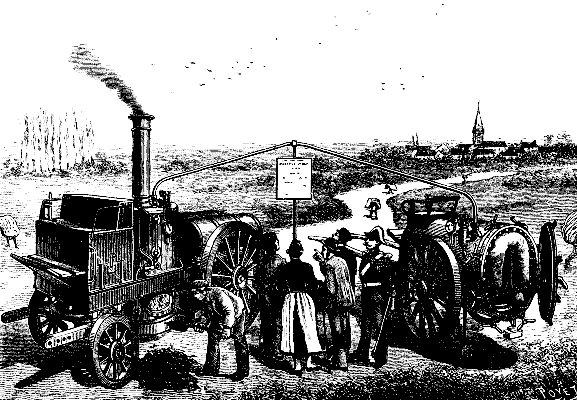

The hot air engine, although theoretically recognized for some time past as the most economical means of converting heat into motive power, has up to the present met with little success. This is due to the fact that the arrangement of the motors of this class that have hitherto been constructed has been such as to render them but slightly practical. In the Benier hot air engine (illustrated herewith), however, obstacles that were once considered insurmountable have been overcome, and the motor presents many advantages over all the types that have preceded it. Among such advantages we shall cite the possibility of utilizing air at a high temperature (1,200 or 1,500 degrees), while the rubbing surfaces remain at a moderate temperature (60 or 80 degrees). The fire grate is placed in the interior of the cylinder, and is traversed by the cold air forced by a pump. The expanded hot gases fill the cylinder and act against the piston directly above the grate.

The type herewith illustrated is of 6 horse power. The motive cylinder, CC', is bolted to the extremity of the frame, A. Upon this latter is fixed a column, B, which carries a working beam, E. This latter transmits the motion of the piston, P, to the shaft, D. A pump, G, placed within the frame, forces a certain quantity of cold air at every revolution into the driving cylinder. The piston of this pump is actuated by the connecting rod, G', jointed to the lever, F', which receives its motion from the rod, F. A slide valve, b', actuated by a cam, regulates the entrance of the cold air into the pump during suction, as well as its introduction into the cylinder. There is a thrust upon the piston during its upward travel, and an escape of hot gas through the eduction valve, h, during the downward travel.

The cylinder is in two parts, C and C'. The piston, which is very long, rubs at its upper end against the sides of the cylinder, C. The lower end is of smaller diameter, and leaves an annular space between it and the cylinder. The grate is at the bottom of the cylinder, C'. The sides of the cylinder at the level of the fire box are protected with a lining of plumbago. When the piston is at the bottom of its travel, the eduction valve closes. The slide valve, b', establishes a communication between the pump chamber and the cylinder. The air contained in the pump is already compressed in the latter to a pressure of nearly a kilogramme at the moment of the communication. This air enters the cylinder, and the communication between the latter and the pump continues until all the air is forced into the driving cylinder, the piston of the pump being at the bottom of its travel, and that of the cylinder about midway.

The air forced by the pump piston enters the cylinder through two conduits, one of which leads a portion of it toward the top of the cylinder, and the other toward the bottom. The lower conduit debouches under the grate, and the air that passes through it traverses the fire box, and the hot gas fills the cylinder. The conduit that runs to the top debouches in the cylinder, C, at the lower limit of the surface rubbed by the piston. The air that traverses this conduit is distributed through the annular space between the piston and cylinder. The hot gas derived from combustion can therefore never introduce itself into this annular space, and consequently cannot come into contact with the rubbing surfaces of the cylinder and piston.

As the quantity of air introduced at every stroke is constant, the work developed at every stroke is varied by regulating the temperature of the gas that fills the cylinder. When the temperature falls, the pressure, and consequently the work developed, diminishes. This result is obtained by varying the respective quantities of air that pass through the fire box and around the piston. In measure as less air passes through the fire box, the quantity that passes around the piston augments by just so much, and the pressure diminishes. A valve, n', in the conduit that runs to the fire box is controlled by the regulator, L', in the interior of the column. When the work to be transmitted diminishes, the regulator closes the valve more or less, and the work developed diminishes.

The coke is put by shovelfuls into a hopper, I. Four buckets mounted upon the periphery of a wheel, I', traverse the coke, and, taking up a piece of it, let it fall upon the cover, J, of the slide valve, j, whence it falls into the cavity of the latter when it is uncovered, and from thence into the conduit, c', of the box, j', when the cavity of the valve is opposite the conduit. From the conduit, c', the coke falls upon the grate.

A small sight hole covered with glass, in the cover, J, permits the grate to be seen when the cavity of the valve is opposite c'.

As in gas engines, a current of water is made to flow around the cylinder, C', in order to keep the sides from getting too hot.

In order to set the engine in motion, we begin by opening the bottom, C, of the cylinder, C', to clean the grate. This done, we close C and introduce lighted charcoal through the conduit, c' (the valve being open). The valve is put in place, two or three revolutions are given to the fly wheel, and the motor starts. The feeding is afterward done with coke.

The parts that transmit motion operate under conditions analogous to those under which the same parts of a steam engine do. The air pump sucks and forces nothing but cold air, and nothing but cold air passes through the distributing slide valve. The pump and valve are therefore rendered very durable. The piston and cylinder, at the points where friction exists, are at a temperature of 60 or 80 degrees. These surfaces are protected against hot gas charged with dust.

The hot gas, which escapes from the cylinder through a valve, has previously been cooled by contact with the sides of the cylinder and by expansion. The eduction valve just mentioned works about like that of a steam engine, and it is only necessary to polish it now and then in order to keep it in good condition.—Annales Industrielles.

Mr. President and Ladies and Gentlemen: It has not been considered the duty of the speaker, in addressing the graduating class, to dwell on the triumphs of science or the advantage of a liberal education. These subjects have already been discussed, in connection with the regular courses of study, better, and more at length, than he could do. We propose rather to try and prepare the minds of the graduates for the practical problems before them.

All young men are impressed with the consciousness of higher powers as they increase their stores of knowledge, and this feeling perhaps reaches its maximum with those who have made a specialty of the investigation and application of physical laws. Young men who have learned how to harness the powers of nature and guide them to do their will are apt to belittle the difficulties they have yet to overcome, and have a false impression of the problems of life. This feeling is shown to a minimum extent by graduates of the Stevens Institute, on account of their careful practical training, in connection with the thorough study of principles; but it has been thought best for one from the outside world to supplement such teaching by calling to mind instances which may have a useful counteracting effect, and, like parables, serve the purpose of illustrative instruction.

Gentlemen of the Class of '87: It was the pleasure of the speaker to address the class of '79, under the title of "How to Succeed," some words of counsel and warning, which, if they left an impression of severity at the time, were apparently so well received afterward that he has been tempted to continue the general subject, with the title of "Your Future Problems." The notation of your future problems will not be found at once among the known quantities, but with x, y, and z, at the other end of the alphabet. Often word symbols will be applicable, expressing at times disappointment and pain, at other times renewed effort, and finally the active phases of individual thought and exertion.

The first serious problem with many of you will be to secure satisfactory engagements. This problem cannot be illustrated by parables. It needs, in general, patient, unremitting, and frequently long continued effort. It may be that the fame of some of you, that have already acquired the happy faculty of making yourselves immediately useful, has already gone abroad and the coveted positions been already assured. To be frank, we cannot promise you even a bed of roses. We have in mind an instance where a superior authority in a large business enterprise who had great respect, as he should have, for the attainments of young gentlemen who have had the opportunities of a technical education, deliberately ordered out a competent mechanical engineer, familiar with the designs required in a large repair shop, and sent in his place a young gentleman fresh from school and flushed with hope, but who from the very nature of the case could know little or nothing of his duties at that particular place. He was practically alone in the drawing room, and did not know where to find such drawings as were required, and candor requires it to be said that he desired to ask many questions about those he did find. The superintendent unfortunately had nothing to do with his appointment, and rather resented it. So he did not trust any of his work, and the new comer was obliged to learn his practical experience at that establishment, where he was known as the mechanical engineer, by having all his work done over by the pattern maker or others, under the eye of the superintendent or master mechanic, and be subjected all the time to the jealousies and annoyances incident to such a method of introduction.

His practical experience was certainly learned under difficulties which I trust none of you may experience. This statement is made that those of you who have not yet obtained positions may not envy those who have, and that each and all of you may be careful not to take a position so far above your experience, if not your capacity, as to become unpleasantly situated in the beginning. The educational facilities you have enjoyed are of such great value in some exceptional cases that the parties thus benefited may do you an injury by leading others to expect that you will be equally valuable in performing duties which require much more practical experience and knowledge of detail than it is possible that you could have obtained in the time you have been here.

The incident is ripe with suggestions. No matter how humble a position you may take in the beginning, you will be embarrassed in much the same way as the young gentleman in question, though it is hoped in a less degree. Your course of action should be first to learn to do as you are told, no matter what you think of it. And above everything keep your eyes and ears open to obtain practical knowledge of all that is going on about you. Let nothing escape you of an engineering nature, though it has connection with the business in hand. It may be your business the next day, and if you have taken advantage of the various opportunities to know all about that particular matter in every detail, you can intelligently act in relation to it, without embarrassment to yourself and with satisfaction to your superior.

Above all, avoid conflict with the practical force of the establishment into which you are introduced. It is better, as we have at another time advised, to establish friendly relations with the workmen and practical men with whom you have to do.

You are to be spared this evening any direct references to the "conceit of learning," but you are asked and advised to bear with the conceit of ignorance. You will find that practical men will be jealous of you on account of your opportunities, and at the same time jealous of their own practical information and experience, and that they may take some pains to hinder rather than aid you in your attempts to actively learn the practical details of the business. The most disagreeable man about the establishment to persons like you, who perhaps goes out of his way to insult you, and yet should be respected for his age, may be one who can be of greatest use to you. Cultivate his acquaintance. A kind word will generally be the best response to an offensive remark, though gentlemanly words of resentment may be necessary when others are present. Sometimes it will be sufficient to say, "I wish a little talk with you by yourself," which will put the bystanders at a distance and enable you to mature your plans. Ascertain as soon as possible that man's tastes; what he reads and what he delights in. Approach him as if you had no resentment and talk on his favorite topic. If rebuffed, tell a pleasant story, and persist from time to time in the attempt to please, until his hardened nature relaxes and he begins to feel and perhaps speaks to others favorably of you. St. Paul has said: "For though I be free from all men, yet have I made myself servant of all that I might gain the more." This is the keynote of policy, and though in humbling yourself you control and hide your true feelings, recollect that all your faculties are given you for proper use.

We have referred to some who have acquired the happy faculty of making themselves immediately useful. This is a much more difficult matter than the words imply. If one of you should be so fortunate as to be ordered to make certain tests almost like those you have already conducted here, or to tabulate the results of tests as you have done it here, or to make inspections akin to those which have been fully explained here, there is every probability the work would be done satisfactorily in the first instance. But let a much simpler case arise, for instance, if a superior hand one of you a letter with the simple instructions, "Get me the facts on that," you may be very much puzzled to know what is to be done and how to do it. It may be that the letter is a request for information in regard to certain work that was carried on in the past, in which case it will be necessary for you to hunt through old records, copy books, engineering notes, drawings, and the like, and get a list of all referring to the subject; to make an abstract of the letters and notes if they are at all complicated; and finally to lay the whole before the overworked superior in a business manner, that he largely from recollection, aided by the references and notes, can write an intelligent answer in a very brief period. The way not to do it would be to say, "Yes, sir," very promptly, go off and not more than half read the letter, do something and be back in five minutes with some question or ill-digested answer; then upon receiving a polite hint as to the method to be employed, go off and repeat the operation the next five minutes; then on receiving a short reply, in what appeared to be an unnecessary tone of voice, get a little flurried perhaps, do worse next time, and in the end feel very unpleasant without having accomplished much, and make the gentleman seeking assistance lament the difficulty in teaching young men practical work.

It is possible, on the contrary, for a young man to exceed his instructions and volunteer advice that has not been asked. If he has unfortunately gone too far for some time and been sharply spoken to, he may fail the next in not fully doing the work intended. Simply putting down a column of figures would not necessarily mean tabulating facts. The arrangement and rearrangement of the columns aid in classifying such facts, so that the results shown by them will be readily seen and a great deal of labor saved in examination. A good rule in a case of this kind is to try and find some work done by other parties of a similar nature, and thereby ascertain what is needed and expected. Reasonable questions to ascertain, where records are to be found and the kind of records accessible, are always proper if made at the proper time without interrupting an immediate train of thought; and with such information as a start, if a young man will endeavor to imagine himself in a place like that of the one who has finally to decide, and try to ascertain just what information will probably be required, then patiently go to work to find and present it in condensed shape, he from that moment really begins to be useful and his services will be rapidly appreciated. It is a good rule always to keep the memoranda obtained in accomplishing a result of this kind; so that if further information is required, the whole investigation need not be made over.

This remark suggests another line of thought. Some young men with quick perceptions get in the way at school of trusting their memories, and omit making complete notes of lectures or of the various tests illustrating their studies. This carelessness follows them into after life, and there are instances where young men, who can make certain kinds of investigations much better than their fellows, and promptly give a statement of the general nature of the results, have, when called on afterward for the details, forgotten then entirely, and their notes and memoranda, if preserved, being of little use, the labor is entirely lost. Such men necessarily have to learn more careful ways in after life. It is a good rule in this, as in the previous case, to make and copy complete records of everything in such shape that they may be convenient for reference and criticism afterward.

One of the important problems with which you will have to deal in the future is the labor question, and it is probable that your very first experience with it may be in direct antagonism with the opinions of many with whom you have heretofore been associated. It is an honor to the feelings of those who stand outside and witness this so-called struggle now in progress between capital and labor, that they believe the whole question can be settled by kindly treatment and reasonable argument. There are some cases that will yield to such treatment, and one's whole duty is not performed till all possible, reasonable, and humanitarian methods are adopted. There has been an excuse for the organization of labor, and it, to some small extent, still exists.

Time was that the surplus of unskilled labor was used on a mercantile basis to reduce wages to such an extent that it was almost impossible to rear a well nurtured, much less a well educated and well dressed family, and, moreover, the hours of labor in some branches of business were so long as to shorten the lives of operatives and make self-improvement impossible. The natural progress of civilizing influence did much to abate many of these evils, but the organization of labor removed sores that had not and perhaps could not have been reached in other ways. Having then an excuse for organization, and supported by the success made in directions where public sympathy was with them, is it to be wondered that they have gone too far in very many cases, and that the leadership of such organization has in many instances been captured by designing men, who control the masses to accomplish selfish ends? Whatever may have been the method of evolution, it is certain that the manufacturing operations of the present day have to meet with elements entirely antagonistic to their interests, and in very many ways antagonistic to the interests of the workingman. The members of many organizations, even of intelligent men, are blindly led by chiefs of various titles, of which perhaps the walking delegate is the most offensive one to reasonable people. This class of men claim the right to intrude themselves into the establishments owned by others, and on the most trivial grounds make demands more or less unreasonable, and order strikes and otherwise interfere with the work of manufacturers, much in the way that we have an idea that the agents of the barbarbous chieftains, feudal lords, and semi-civilized rulers collected taxes and laid burdens in earlier historical times. Necessarily these men must use their power so as to insure its permanency. If strikes are popular, strikes must be ordered. If funds run low, excuses for strikes, it is believed, in many cases are sought, so as to stir the pulses of those who sympathize with the labor cause.

Co-operation has been suggested as a cure for the evil, and there are cases where it has apparently succeeded, in connection with the earlier forms of labor organization. The ambition of later labor leaders almost prevents this remedy being of effect. It may be possible still with very intelligent workmen, isolated from the large mass of workmen in the country towns, to feel an interest in co-operation; but such inducements, or the higher ones of personal kindness to employes or their families, are not of much effect in large manufacturing centers. As soon as dissatisfaction exists in one mill or manufactory, all similar employes are ordered out. The final result will be that combinations of employers must follow the combination of employes, and those who have always been strong in the past will be stronger in the future, as has appeared to be the case in many contests that have already taken place. If there are any real abuses of power by the employers, such as requiring work for unusual hours or at less than living rates, the first thing to do is to correct these abuses, so that complaints will not be upon a sound foundation. Some men, when the labor epidemic strikes their places, have sufficient force of character and influence with their men to avert the blow for some time. Others find it is policy to compromise with the representatives until a plan of action, conciliatory, offensive, or defensive, can be determined upon. The whole matter must be considered one of policy rather than of principles. The class of men to be dealt with do not talk principles except as an excuse to secure their ends.

In spite of everything, there will be times when no compromise is possible and you will be called upon to take part in defending your employers' interests against what is called a "strike." You can do so with heart when you know the employes are all well paid, and particularly, as is frequently the case, when the labor organizers and walking delegates claim that some old, tried foreman shall be dismissed because they do like him, really because he has not been a tool in carrying out their plans, and they defiantly acknowledge that their war is against non-union labor, and that they have organized your men and forced a strike to require your establishment to become as it is called a "union shop." If your deluded employes were permitted simply to go away and let you alone, and you were permitted to employ others at the reasonable wages you were paying, the problem would be a simple one. The principal labor organizations claim that everything they do is by peaceable methods, but this, like many things said, is simply to deceive, for if you attempt to employ other assistants and carry on your business independently, you will surely find that well known roughs are assembled who never do anything without they are paid for it by somebody, that your men are assaulted by such persons, and while the labor organizers talk about peaceable methods and urge them aloud in public, in case one of the roughs is arrested, the loud talkers are the first to go bail for the defender, and you will feel morally sure that the sympathizing crowd with the roughs who make the assaults are all part of or tools of the organization.

At such times, you will find your old employes standing around the street corners, persuading other men not to go to work and thus interfere with what are called the true interests of labor. Any new employe who has to go in the street will be first met with inducements of other employment, with offers of money, afterward with threats, and, if opportunity occurs, with direct assault. All the features of persuasion, intimidation, and violence will be carried out as demanded, and strangers to everybody in the vicinity, but well known as experienced leaders in this kind of work in other places, be brought in to endeavor to make the strike a success. Then, young men, is the time to show your pluck, and our experience is that educated young men will do so every time. They can be depended upon to go straight ahead with duty through every danger, bearing patiently everything that may be said, defending themselves with nature's weapons as long as possible, and without fear using reserve weapons in case real danger of life is imminent.

In carrying through a very important strike against a mere desire to control and not to correct abuses, your speaker desires to pay the highest tribute to a number of educated young men, mostly from the technical schools, who fearlessly faced every danger, and by their example stimulated others to do their duty, and all participated in the results obtained by a great success.

We would not by such references fire your hearts to a desire to participate in such an unpleasant contest. It is the duty of all to study this problem intelligently and earnestly, with a view of overcoming the difficulties and permitting the prosperity of the country to go on. While conciliation may be best at some times, policy at another, and resistance at another, we must also be thinking of the best means to prevent further outbreaks. It would seem to be true policy not to interfere with organization, but to try and direct it into higher channels. Those of the humanitarians who claim that the disease will be rooted out eventually by a more general and better education are undoubtedly largely in the right, notwithstanding that some fairly educated men have acted against their best interests in affiliating with the labor organizations. It seems to the speaker that enough instances can be collected to show the utter folly of the present selfish system, based, as it is, entirely on getting all that is possible, independent of right in the matter, and by demanding equal wages for all men, tending to lower all to one common degradation, instead of rewarding industry and ability and advancing the cause of civilization.

Labor should not be organized for selfish ends, but for its own good, so as to secure steady and permanent employment, rather than prevent it by impracticable schemes and unwise methods, which will cripple manufacturers and all kinds of industry. The men should organize under the general laws of the State, so that their leaders will be responsible to the laws and can be indicted, tried, and punished in case they misappropriate funds or commit any breach of trust; and such laws should be amended if necessary, so that wise, responsible leaders of the organizations can contract to furnish labor for a certain time at a fixed price, when manufacturers can make calculations ahead as to the cost of labor the same as for the cost of material, and have such confidence that they will use all their energies to do a larger amount of business and benefit the workingman as well as themselves by furnishing steady employment. Such a plan as is here outlined can readily be carried into effect by selecting better men as leaders. It is well known how well the organization known as the locomotive brotherhood is conducted, and it should be an example to others. It has had its day of dissensions, when the best counsels did not prevail, which shows that any organization of the kind, no matter how well conducted, may be diverted by its leaders into improper channels.

When organized under the laws of the State and under by-laws designed to secure steady employment, rather than any artificial condition of things in regard to pay hours, and continuance of labor, the true interests of the workman will be advanced. It may be that some one of you will develop a talent in the direction of organization and be the means of aiding in the solution of this great problem. Please think of the matter seriously, watch the law of evolution while you are advancing your professional knowledge, and if the opportunity offers, do all you can to aid in a cause so important and beneficent.

One writer has criticised the technical schools because they do not teach mechanical intuition. The schools have enough to do in the time available if they teach principles and sufficient practice to enable the principles to be understood. The aptitude to design, which must be what is meant by mechanical intuition, requires very considerable practical experience, which you will readily learn if you do not keep yourself above it. If you have used your leisure hours to study why a certain piece of mechanism was made in a certain way rather than in another; if you have wondered why one part is thick in one place rather than in another, apparently in defiance of all rules of the strength of material; if you have endeavored to ascertain why a particular device is used rather than another more evident one; if you have thought and studied why a boss is thrown in here and there in designs to receive bolts or to lengthen a journal, and if you have in your mind, by repeated observation, a fair idea of how work is designed by other people, the so-called mechanical intuition will be learned and found to be the combination of common sense and good practice.

You will observe that some details have been copied for years and years, although thoughtful men would say they are not the best, simply because they are adapted to a large amount of work already done. This is particularly true of the rolling stock on railroads. The cost of a change in starting in a new country might be warranted, but it practically cannot be done when the parts must interchange with so much work done in other parts of the country. You will find in other cases that the direct strain to which a piece of mechanism is subjected is only one of the strains which occur in practice. A piece of metal may have been thickened where it customarily broke, and you may possibly surmise that certain jars took place that caused such breakages, or that particular point was where the abuse of the attendant was customarily applied.

Wherever you go you will find matters of this kind affecting designs staring you in the face, and you will soon see why a man who has learned his trade in the shop, and from there worked into the drawing room with much less technical information than you have, can get along as well as he does. Reserve your strength, however. Your time will come. Whenever there is a new departure to be taken, and matters to be worked out from the solid which require close computation of strains or the application of any principles, your education will put you far ahead, and if you have, during the period of what may be called your post-graduate course, which occurs during your early introduction into practical life, been careful to keep your eyes and ears open so as to learn all that a man in practical life has done, you will soon stand far ahead.

Reference was made to the use of leisure hours. Leisure hours can be spent in various ways. For instance, in studying the composition and resolution of forces and the laws of elasticity in a billiard room, the poetry of motion, etc., in a ball room, and the chemical properties of various malt and vinous extracts in another room; but the philosophical reason why certain engineering work is done in the way it is, and the proper way in which new work shall be done of a similar character and original work of any kind carried on, can only be learned by cultivating your powers of observation and ruminating on the facts collected in the privacy of one's own room, away from the allurements provided for those who have nothing to do. No one would recommend you to so separate yourself from the world as to sacrifice health and strength, or to become a recluse, even if you did learn all about a certain thing.

Remember, however, that the men who have accomplished most in this world worked the longest hours, and any one with a regular occupation must utilize his leisure hours to obtain prestige. The difference between one man and another of the same natural ability lies entirely in the amount of his information and the facility with which he can use it. Life is short, and you must realize that now is your opportunity. If any diversion in the way of pleasure or even certain kinds of congenial work is offered, consider it in connection with the question, "Will this be conducive to my higher aim?" This implies that you have a higher aim; and if you have it, and weigh everything in this way, you will find that every moment of exertion adds something to your storehouse of information and brings you nearer to the accomplishment of that higher aim.

In closing, we thank the ladies and gentlemen present for their close attention to details of special interest only to those engaged in technical study or practice.

We congratulate you, young gentlemen of the class of '87, for the success you have thus far obtained, and trust that you will persevere in well doing and win greater success in the future. We need hardly state that all that has been said was in a spirit of kindness, and we feel assured that much of it has been seconded by your parents, to whom no less than to all parents here present off or on the stage, the speaker not excepted, a serious, thoughtful problem has been, still is, and will continue to be to many, "What shall we do with our boys."—Stevens Indicator.

An address to the graduating class, Stevens Institute, Hoboken, N.J., 1887.

We were recently witness of an experiment made at Eragny Conflans on the steam yacht Flamboyante. It was a question of testing a new vaporizer or burner for liquid fuel. The experiment was a repetition of the one that the inventor, Mr. G. Dietrich, recently performed with success in the presence of Admirals Cloue and Miot.

The Flamboyante is 58 ft. in length, 9 ft. in width, draws 5 ft. of water, and has a displacement of 10 tons. She is provided with a double vertical engine supplied by a Belleville boiler that develops 28 horse power. The screw makes 200 revolutions per minute, and gives the yacht a speed of 6½ knots.

Mr. Dietrich's vaporizer appears to be very simple, and has given so good results that we have thought it of interest to give our readers a succinct description of it. In this apparatus, the inventor has endeavored to obtain an easy regulation of the two essential elements—naphtha and steam.

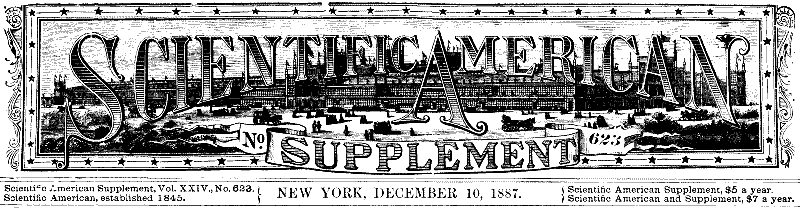

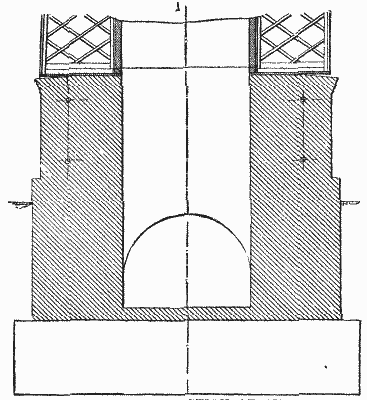

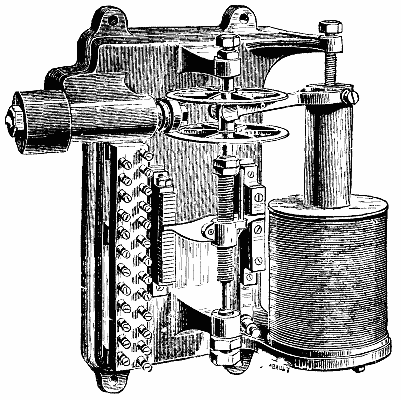

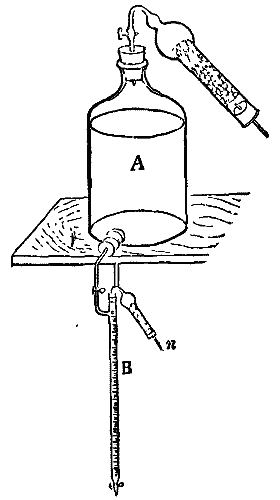

Fig. 1 represents the apparatus in section. The steam enters through the tubulure, A, and finds its way around the periphery of a tuyere, D. It escapes with great velocity, carries along the petroleum that runs from two lateral tubulures, B (Fig. 2), and throws it in a fine spray into the fireplace, through the nozzle, C (Fig. 1), which is flattened into the shape of a fan opened out horizontally. The mixture at once ignites in contact with the hot gases, and gives a beautiful, long, clear flame. The air necessary for the combustion is sucked through the interior of the nozzle, H, which is in front of the tuyere. It will be seen that the current of steam can be regulated by moving the tuyere, D, from or toward the eduction orifice. This is effected through a maneuver of the hand wheel, F. In the second place, the flow of the petroleum is made regular by revolving the hand wheel, G, which gives the piston, O, a to and fro motion in the tuyere, D.

FIG. 1—THE DIETRICH PETROLEUM BURNER.

The regulation may be performed with the greatest ease. It is possible to instantly vary, together or separately, the steam and the petroleum. Under such circumstances, choking is not to be feared at the petroleum orifice, where, according to experiment, the thickness of the substance to be vaporized should not be less than 0.04 of an inch.

The petroleum might evidently be made to enter at A and the steam at B; but one of the conclusions of the experiments cited is that the performance is better when the jet of steam surrounds the petroleum. It will be understood, in fact, that by this means not a particle of the liquid can escape vaporization and, consequently, combustion. Moreover, as the jet of petroleum is completely surrounded by steam its flow can be increased within the widest limits, and this, in certain cases, may prevent an obstruction without much diminishing the useful effect of the burner.

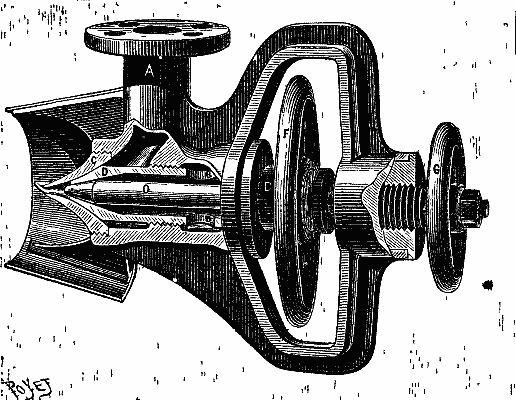

The apparatus is easily and rapidly taken apart. It it is only necessary to remove the nozzle, C, in order to partially clean it. It would even seem that the cleaning might be done automatically by occasionally reversing the flow of the steam and petroleum. However efficacious such a method might prove, the apparatus as we have described it can be very easily applied to any generator. Fig. 2 represents it as applied to the front of a furnace provided with two doors. A metallic box, with two compartments, is placed on one side of the furnace, and is provided with two stuffing boxes that are capable of revolving around the steam and petroleum pipes. The latter thus form the pivots of the hinge that allows of the play of the vaporizers and piping.

FIG. 2—THE BURNER APPLIED TO THE FURNACE OF A BOILER.

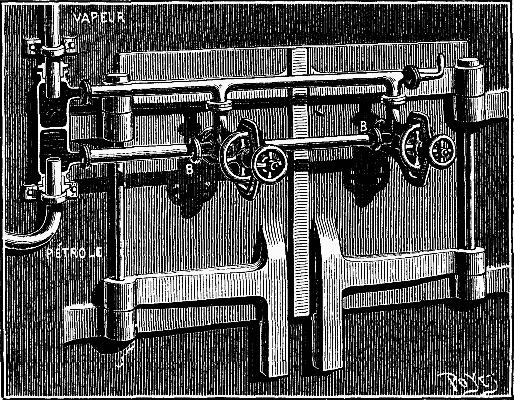

It was in this way that Mr. Dietrich arranged his apparatus in an experiment made upon a stationary boiler belonging to a Mr. Corpet. The experiment was satisfactory and led to the adoption of the arrangement shown in Fig. 3. The fire bridge is constructed of refractory bricks, and the majority of the grate bars are filled in with brick. The few free bars permit of the firing of the boiler and of access of air to the interior of the fire box. Under such circumstances, the combustion is very regular, the furnace does not roar, and the smoke-consuming qualities are perfect.

FIG. 3—APPLICATION OF THE BURNER TO A RETURN FLAME BOILER.

In the experiment on the Flamboyante, the boiler was provided with but one apparatus, and the grate remained covered with a layer of ignited coal that had been used for firing up in order to obtain the necessary pressure of steam to set the vaporizer in operation. This ignited coal appeared to very advantageously replace the refractory bricks, the role of which it exactly fulfilled. It has been found well, moreover, to break the flames by a few piles of bricks in the furnace, in order to obtain as intimate a mixture as possible of the inflammable gases.

It is to be remarked that firing up in order to obtain the necessary steam at first is a drawback that might be surmounted by using at the beginning of the operation a very small auxiliary boiler. The main furnace would then be fired by means of say a wad of cotton. But, in current practice, if a grate and fire be retained, the firing will perhaps be simpler.

With but one apparatus, the pressure in the Flamboyante's boiler rose in a few minutes from 6 to 25 pounds, and about a quarter of an hour after leaving the wharf the apparatus had been so regulated that there was no sign of smoke. This property of the Dietrich burner proceeds naturally from the use of a jet of steam to carry along the petroleum and air necessary for combustion. It is, in fact, an Orvis smoke consumer transformed, and applied in a special way.

It must be added that the regulating requires a certain amount of practice and even a certain amount of time at every change in the boat's running. So it is well to use two, and even three, apparatus, of a size adapted to that of the boiler. The regulation of the furnace temperature is then effected by extinguishing one or two, or even three, of the apparatus, according as it is desired to slow up more or less or to come to a standstill.

The oil used by Mr. De Dosme on his yacht comes from Comaille, near Antun. The price of it is quite low, and, seeing the feeble consumption (from 33 to 45 lb. for the yacht's boiler), it competes advantageously with the coal that Mr. De Dosme was formerly obliged to use.—La Nature.

[Continued from SUPPLEMENT, No. 622, page 9935.]

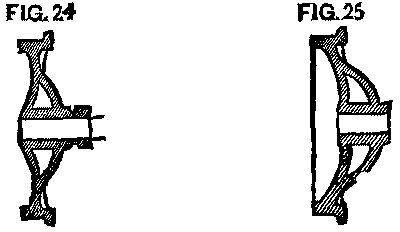

Many of the wheels that were still in use with the long hub were put into a lathe, and a groove was cut an inch and a half back from the face, leaving our cast collar, which was easily split off as before. (Fig. 24.)

With tender wheels, as with our car wheels, the case was different. Originally, the axle for the 5 ft. gauge was longer than for the 4 ft. 9 in.; but latterly the 5 ft. roads had used a great many master car builders' axles for the 4 ft. 9 in. gauge, namely, 6 ft. 11¼ in. over all, thus making the width of the truck the same as for 4 ft. 9 in. gauge. To do this a dished wheel, or rather a wheel with a greater dish by 1½ in. than previously used, was needed, so that the tread of the wheel could be at its proper place. (See Fig. 25.) There were, of course, many of the wheels with small dish and long axles still in use. Their treatment, however, when the day of change came, did not vary from that of the short axle.

FIG. 24 and FIG. 25

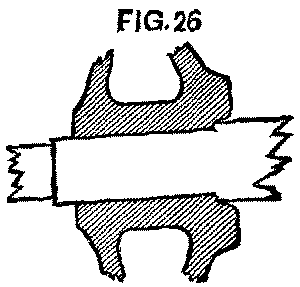

It had been the rule for some years that all axles should be turned back 1½ in. further than needed; but unfortunately the rule had not been closely followed, and many were found not to be so turned. To make the matter worse, quite a number of the wheels were found to have been counterbored about ½ in. deep at the back end, and the axle turned up to fit this counterbore; a good idea to prevent the running in, in case the wheel worked loose, but bad from the standpoint of a change of gauge. In such cases the wheels had to be started off before the axle could be turned back, so that the wheels could be pushed on in their proper position. (Fig. 26.)

FIG. 26

If the work was done where they had a lathe large enough to swing a pair of wheels, they were pressed off but half an inch, the wheels swung in the lathe, the axles turned back 1½ in., and the wheels then pressed on 2 in. or 1½ in. inside of their first position.

Where no large lathe was in use, the wheels came entirely off before the axles could be turned back. The work in the former case was both the quicker and the cheaper. Where the large lathes were used they were either set down into the floor, so a pair of wheels would easily roll into place, or a raised platform was put before the lathe, with an incline up which the wheels were rolled and then taken to the lathe. These arrangements were found much quicker and cheaper than to hoist the wheels up, as is usually done.

In pressing the wheels on, where the axles had previously been turned back, much trouble was at first experienced because of the rust that had gathered upon the turned part behind the wheel, forming a ridge over or upon which the wheel must be pushed. Some of the roads, at the start, burst 10 or 15 per cent. of the wheels so pressed on. By saturating this surface with coal oil, however, it was found that the rust was easily removed and little trouble was had. It was found, sometimes, that upon axles newly turned back a careless workman would leave a ridge at the starting point of the turning. Frequently also the axles were a little sprung, so that the new turning would be a little scant upon one side when compared with the old surface, and upon the opposite side a little full. As an indication that these difficulties were overcome as they appeared, I will say that upon our line only 202 wheels burst out of nearly 27,000 pressed on—an exceedingly small percentage.

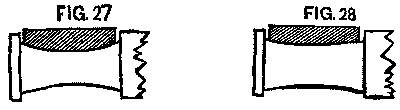

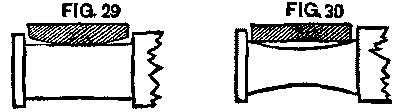

After the change upon the early roads they were troubled for weeks with hot boxes, caused, as we believed, by the changing of brasses. A brass once fitted to a journal will work upon it without trouble, but when placed upon some other journal will probably not fit. If the journal had been worn hollow (and it was surprising to see how many were so worn), the brass would be found worn down to fit it. (See Fig. 27. Exaggerated, of course.)

FIG. 27 and FIG. 28

The next wheel may have an axle worn little or none. (See Fig. 28)

Now, if these brasses are exchanged, we have the conditions as shown in Figs. 29 and 30, and we must expect they will heat. The remedy was simply to keep each brass upon its own journal. To do this the brasses were fastened to the axle by a piece of small wire, and went with it to the lathe and press. When its truck was reached, the brass was there with its journal. Worn-out brasses, of course, could not be put in, and new ones were substituted. The little trouble from that source that followed the change showed the efficacy of the remedy.

FIG. 29 and FIG. 30

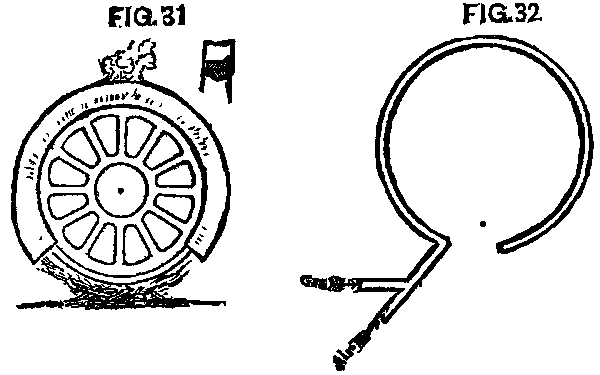

The manner in which the tires of engines were to be changed, when the final day came, was a serious question. The old-fashioned fire upon the ground could not be thought of. The M. & O. had used a fire of pine under the wheel, which was covered by a box of sheet iron, so arranged that the flame and heat would be conveyed around the tire, and out at an aperture at the top. (Fig. 31.) Many thought this perfect, while others were not satisfied, and began experiments for something better. A device for using gas had been patented, but it was somewhat complicated, as well as expensive, and did not meet with general favor. A very simple device was soon hit upon. A two inch pipe was bent around in a circle a little larger than the outer rim of the wheel. Holes 1/10 in. in diameter and 3 or 4 in. apart were drilled through the pipe on the inside of the circle. To this pipe was fastened another with a branch or fork upon it. To one branch or fork was connected a gas pipe from the meter, while to the other was connected a pipe from an air pump. With the ordinary pressure of city gas upon this pipe it was found that the air pump must keep an air pressure of 40 pounds, that the air and gas might mix properly at the branch or fork, so we could get the best combustion and most heat from our "blowpipe," for such it was. (Fig. 32.)

FIG. 31 and FIG. 32

We were able to heat a tire so it could be moved in ten to twenty minutes, and the machine may be said to have been satisfactory.

Gas, however, was not to be had at all places where it would be necessary to change tires, and the item of cost was considerable.

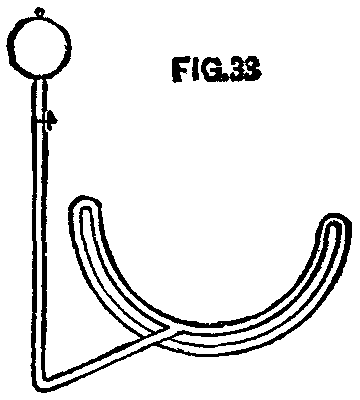

To reach a result as good, if possible, experiments were begun with coal oil (headlight oil). They were crude and unsatisfactory at first, but soon success was reached.

A pipe was bent to fit the lower half of a wheel pretty closely and then turned back under itself about the diameter of the pipe distant from it. This under part had holes 1/10 in. diameter and 3 or 4 in. apart drilled upon its upper side or under the upper pipe. Connected with the upper pipe at its center was a pipe which ran to one side and up to the can containing the kerosene. Between the can and the pipe under the wheel was a stop cock, by which the flow of oil could be controlled.

FIG. 33

To use the device, open the cock and let a small amount of oil flow; apply fire to the pipe under the wheel, and the oil in the upper pipe is converted into gas, which flows out of the small holes in the lower pipe, takes fire, and heats not only the tire, but the upper pipe, thus converting more oil into gas. We had here a lot of blue flame jets and the same result as with gas, but at less cost. We had also a machine that was inexpensive and easily handled anywhere. Boxes were placed over the upper parts of the wheels, that the heat might pass closely to the tire. This device was extensively used by our people, and with great satisfaction. In one way care had to be taken, viz.: That in starting the fire it did not smoke and cover the tire with carbon or "lampblack," which is a non-conductor of heat.

Experiments were made with air forced through gasoline, and with oil heated in a can to form gas. There was more danger in either of these than with our blowpipe device, and no better results were obtained, though the cost was greater.

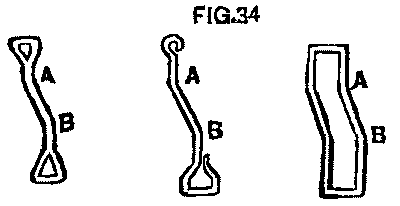

With the change of the wheels, the brakes had to be changed the same amount, that is, each one set in 1½ in. This it was thought would either require new hangers or a change in the head or shoe in some way. We found that the hangers could easily be bent without removal. Fig. 34 shows three hangers after passing through the bending process. A short lever arranged to clasp the hanger just below the point, A, was the instrument; a forked "shore" is now placed, with the fork, against the point, A, and the other end against the car sill; press down on the lever and you bend the hanger at A; lower the lever to a point just below B, reverse the process, and you have the bend at B; the whole thing taking less than two minutes per hanger. A new bolt hole, of course, has been bored in the brake beam 1½ in. inside the old hole. It takes but a short time after this to change the position of the head and shoe.

FIG. 34

Before the day of change, a portion of the spikes were drawn from the inside of the rail to be moved, and spike set 3 in. inside of the rail. As a rule two spikes were drawn and the third left. At least every third spike was set for the new gauge, and in some cases every other one.

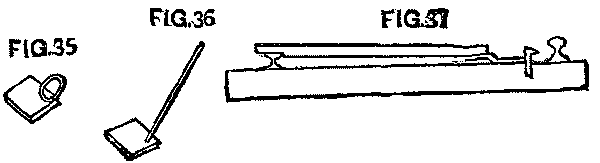

There were several devices with which to set the spike. A small piece of iron 3 in. wide was common, and answered the purpose well. This had a handle, sometimes small, just large enough for the hand to clasp, while others had a handle long enough for a man to use it without stooping down. (See Figs. 35 and 36.) Another device is shown in Fig. 37, so arranged that the measurements were made from the head of the other rail. This was liked best, and, it is thought, gave the best results, as the moved rail was more likely to be in good line than when the measurements were taken from the flange.

FIG. 35, FIG. 36 and FIG. 37

It was intended that great care should be taken in driving the spikes, that they were in the proper place, square with the rail, and left sticking up about an inch.

The ties, of course, were all adzed down before the day of change.

"Handspikes" were originally used to throw the rails, as were lining bars.

We found, however, that small "cant hooks" were more easily handled and did better work. The first were made like Fig. 38, with a spike in the end of a stick, while the hook was fastened with a bolt about 10 or 12 inches above the foot.

FIG. 38 and FIG. 39

We afterward made them of a 1¼ in. rod, 3½ ft. long, pointed at one end, with a ring shrunk on 1 ft. from the bottom. Then the hook was made with an eye, as shown in Fig. 39, which slipped down over the top of the main rod. This was simple and cheap, and the iron was to be used for repair purposes when this work was done.

Upon the system with which the writer was connected we had some branches where we could experiment upon the moving of the rail. Between Selma and Lauderdale the traffic was light, and at Lauderdale it connected with the Mobile & Ohio Railroad, which was narrow, and to which all freight had to be transferred, either by hoisting the cars or by handling through the house. By changing our gauge we would simply change the point of transfer to Selma. Here was a chance to experiment upon one hundred miles and cause little trouble to traffic. We could see the practical workings of our plans, and, at the same time, leave less to do on the final day. Upon the 20th of April we did this work. It had been our plan to do it somewhat earlier, but floods prevented.

Most of the rail was old chair iron, short, and consequently more time was used in making the change than would have been required had our work been on fishplate rail. Our sections here were about eight miles long, and we arranged our men on the basis blocked out by the committee, viz., 24 to 26 men to the section, consisting of 6 spike pullers, 4 throwing rails, 12 spikers, 2 to push the cars and carry water.

We soon found 5 ft. cars useless, and threw them into the ditch to be picked up at some future time.

The men were spread out so as not to be in each other's way, and when the organization was understood and conformed to, it worked well. One gang changed 5 miles in 5 hours and 10 minutes, including a number of switches. We found, however, and it was demonstrated still more strongly on later work, that after 5 or 6 miles the men began to lag.

We believed we had the best results when we had sections of about that length.

It was arranged that two sections, alternately, commenced work together at one point, working from each other and continuing until the force of another section was met, working from the opposite direction.

The foreman in charge was expected to examine the work and know that all was right. The push car which followed was a good test as to gauge.

A work train was started from each end with a small force (20 or 25 men) to run over the changed track. This train, of course, had been changed on a previous day to be ready for this work.

If a force was overtaken by this train with its work not done, the men on the train were at once spread out to aid in its completion. This done, the train ran on.

Not until this was done was a traffic train allowed to pass over the track. The same rule was followed upon all the work.

Upon the final day it was required that upon all high trestles and in tunnels the track should be full-spiked before being left or a train let over. This took extra time and labor, and possibly was not necessary; but it was a precaution on the side of safety.

Upon the day of the change of the Alabama Central Division (Selma to Lauderdale), superintendents of other divisions, with their road masters, supervisors, master mechanics and many section foremen, were sent over to see the organization and work and the preparations that had been made. Many of them lent a helping hand in the work. They saw here in practice what had only been theory before.

About a week before the general change that portion of the road between Rome, Ga., and Selma, Ala., about 200 miles, was changed, and again men from other divisions were sent to see and aid in the work. So when the final day came, the largest possible number of men were able to work understandingly.

On the last day of May the Memphis & Charleston, Knoxville & Ohio, and North Carolina branch were changed, and on June 1 the line from Bristol to Chattanooga and Brunswick.

Other roads changed their branch lines a day or two before the 1st of June; but the main lines, as a rule, were changed on that day.

It was a small matter to take care of the cars and arrange the train service so there should be no hitches. It was not expected that connections would move freight during the 48 hours prior to the change, and these days were spent in clearing the road of everything, and taking the cars to the points of rendezvous. All scheduled freight trains were abandoned on the day prior to the change, and only trains run to such points.

Upon the East Tennessee system these points were Knoxville, Rome, Atlanta, Macon, Huntsville, and Memphis, and to these points all cars must go, loaded or empty, and there they were parked upon the tracks prepared for the purpose. Passenger trains were run to points where it had been arranged to change them, generally to the general changing point.

Most of the Southern roads have double daily passenger service. Upon all roads one of these trains, upon the day of change, was abandoned, and upon some all. Some, even, did not run till next day.

We were able to start the day trains out by 10 or 11 o'clock A.M., and put them through in fair time. Of course, no freights were run that day, and the next day was used in getting the cars which had been changed out of the parks and into line. So our freight traffic over the entire South was suspended practically three days.

The work of changing was to commence at 3:30 A.M., but many of the men were in position at an earlier hour, and did commence work as soon as the last train was over, or an hour or so before the fixed time. Half-past three A.M., however, can be set down as the general hour of commencement.

For five or six hours in the cool morning the work went on briskly, the men working with much more than ordinary enthusiasm. But the day was warm, and after 9 or 10 A.M. it began to lag. All was done, however, before the day was over, and safe, so that trains could pass at full speed.

The men all received $1.50 for the work, whether it was finished early or late in the day, and were paid that afternoon as soon as the work was done. Tickets were given the men, which the nearest agent paid, remitting as cash to the treasurer.

On some lines it was deemed best to offer prizes to those who got through first.

Reports showed some very early finishes. But the facts seem to have been that under such encouragement the men were apt to pull too many spikes before the change and put too few in while changing. They were thus reported through early, but their work was not done, and they took great chances.

It was by most considered unwise to offer such prizes, preferring to have a little more time taken and be sure that all was safe. Such lines seemed to get their trains in motion with as much promptness as others. This, with freedom from accident, was the end sought.

It was found after the work had been done that there had been little inaccuracies in driving the gauge spike, to which the rail was thrown, probably from various causes. The rail to be moved may not always have been exactly in its proper place, and then the template in the hurry may not have been accurately placed, or the spike may have turned or twisted.

Whatever was the cause, it was found that frequently the line on the moved side was not perfect, and, of course, many spikes had to be drawn and the rail lined up and respiked. The more careful the work had been done, the less of this there was to do afterward. With rough track this was least seen. The nearer perfect, the more noticeable it was.

Of course, we all planned to get foreign cars home and have ours sent to us. But when the interchange stopped, we found we had many foreign cars, which, of course, had to be changed. This subject had come up in convention and it had been voted to charge three dollars per car when axles did not need turning, and five dollars where they did. By comparison with the cost of changing, as shown in this paper, it will be seen that to our company, at least, there was no loss at these figures.

The following tables will explain the work done upon the Louisville & Nashville and East Tennessee, Virginia & Georgia systems.

It is to be regretted that the writer has not at hand information regarding other roads, that fuller statements and comparisons might be made and the showings be of greater value.

The figures of the Mobile & Ohio are added, having been compiled from the annual report of that road.

MOBILE & OHIO RAILROAD.

(Compiled from Annual Report.)

| Number Changed. | Cost of Labor. | Cost of Material. | Total Cost. | Average Cost. | |

|---|---|---|---|---|---|

| Engines and tenders. | 47 | $ 8,031.42 | $ 7,276.86 | $15,308.28 | $325.70 |

| Pass., bag., ex. cars. | 55 | 439.37 | 104.25 | 542.62 | 9.87 |

| Freight cars, 1,361. Freight trucks, 107½. | 1,468½ | 5,719.03 | 739.57 | 6,458.60 | 4.40 |

| Lever and push cars. | 143 | 1,427.55 | 476.93 | 1,904.48 | 13.32 |

| Miles. | |||||

| Track (inc. sidings). | 583.5 | 17,109.53 | 7,275.14 | 24,384.87 | 41.79 |

| Bridges. | 583.5 | 1,896.60 | 190.00 | 2,086.60 | 3.58 |

| Track tools. | 583.5 | 170.72 | 1,405.74 | 1,576.46 | 2.70 |

| Shop tools. | 583.5 | 419.70 | 2,982.90 | 3,402.60 | 5.83 |

| Temp. side tracks. | 12.09 | 1,958.94 | 372.37 | 2,331.31 | 192.83 |

| Switching cars. | 1,398.18 | 16.50 | 1,414.68 | ||

| Car hoists. | 2,499.38 | 4,419.34 | 6,918.72 | ||

| Total cost. | $41,069.42 | $25,259.60 | $66,329.02 | ||

| Total average cost per mile. | $113.68 | ||||

LOUISVILLE & NASHVILLE RAILROAD.

(Compiled from Annual Report.)

| Miles of track | —Main line | 1,893.7 | ||

| —Side track | 196.3 | |||

| ———— | 2,090.0 | |||

| Track. | Total. | Cost per Mile. | ||

|---|---|---|---|---|

| Section labor | —Before day of change | $28,106.60 | ||

| —On day of change | 20,090.42 | |||

| —After day of change | 19,713.19 | |||

| ———— | $67,910.21 | $32.49 | ||

| Carpenter labor | 3,799.19 | 1.82 | ||

| Spikes | 20,873.70 | 9.99 | ||

| Switches | 6,331.85 | 3.03 | ||

| Tools | 2,749.50 | 1.31 | ||

| Hand cars and sundries | 5,691.39 | 2.72 | ||

| Total | $107,855.84 | $51.36 | ||

| Equipment. | ||||

| Number. | Total. | Average Cost. | ||

| Locomotives | 264 | $53,480.98 | $202.58 | |

| Cars (300 of these passenger—3.5%) | 8,537 | 49,577.20 | 5.81 | |

| Total cost | $210,414.02 | |||

| Total average cost per mile | $100.67 | |||

EAST TENNESSEE, VIRGINIA & GEORGIA SYSTEM.

| Number Changed. | Cost of Labor. | Cost of Material. | Total Cost. | Average Cost. | |

|---|---|---|---|---|---|

| Engines and tenders. | 180 | $ 8,227.47 | $ 2,904.30 | $ 11,131.77 | $ 61.82 |

| Pass., bag., and mail cars. | 168 | 734.93 | 59.67 | 794.60 | 4.73 |

| Freight cars and cabooses. | 5,175 | 17,425.57 | 1,224.08 | 18,649.65 | 3.60 |

| M. of W. cars. | 439 | 2,038.44 | 549.47 | 2,587.91 | 5.89 |

| Miles Track. | |||||

| Track (inc. sidings). | 1,532.7 | 27,718.17 | 40,912.09 | 68,630.26 | 44.78 |

| Bridges. | 1,532.7 | 1,808.57 | 200.00 | 2,008.57 | 1.31 |

| Track tools. | 1,532.7 | 194.48 | 2,573.83 | 2,768.31 | 1.80 |

| Storage tracks, inc. taking up. | 37.02 | 9,825.41 | 1,481.59 | 11,307.00 | 305.44 |

| Shop tools. | 472.20 | 2,728.30 | 3,200.50 | ||

| Total cost. | $68,445.24 | $52.633.33 | $121,078.57 | ||

| Total average cost per mile. | $ 79.06 | ||||

| Axles condemned | 577 |

| Wheels condemned | 754 |

| Wheels burst | 202 |

| New axles used | 1,102 |

| New wheels used | 2,783 |

| Axles turned back | 8,316 |

| Wheels pressed on without turning axle | 23,952 |

| New brasses used | 10,723 |

| Cars narrowed (not including lever or push cars) | 5,343 |

| Engines narrowed | 180 |

| Average cost of new centers and crank pins, etc | $264.46 |

| Average cost of cutting off hub and pressing wheels and new pins | 130.67 |

| Average cost of pressing old tires on old centers | 29.08 |

| Average cost of pressing old tires on broad centers | 31.83 |

| Average cost of labor putting on new tires | 22.94 |

COMPARATIVE STATEMENT OF AVERAGE COST OF VARIOUS ITEMS OF WORK.

| M. & O. R.R. | L. & N. R.R. | E.T.,V. & G. R.R. | Average. | |

|---|---|---|---|---|

| Engines and tenders—per engine | $325.70 | $202.58 | $61.82 | $196.70 |

| Pass., bag., and ex. cars—per car | 9.87 | 25.81 | 4.73 | 6.80 |

| Freight cars, per car | 4.40 | 35.81 | 3.60 | 4.60 |

| M. of W. cars, per car | 13.32 | 2.72 | 5.89 | 7.31 |

| Track (inc. sidings bridges, etc.), per mile | 45.37 | 47.83 | 46.09 | 46.26 |

| Track tools, per mile | 2.70 | 1.31 | 1.80 | 1.94 |

| Temporary side tracks, per mile | 192.83 | 305.44 | 249.13 | |

| Total per mile of track, inc. sidings | $113.68 | $100.67 | $ 79.06 | $ 97.80 |

NOTE—Since the preparation of this paper the general manager of the Norfolk & Western Railroad has kindly furnished the following items of expense for that line:

| No. | Cost. | Average Cost. | ||

|---|---|---|---|---|

| Engines and tenders | 95 | $37,730.00 | $397.16 | |

| Cars (all kinds) | 3,615 | 37,994.65 | 10.51 | |

| Track, miles (including sidings) | 597.5 | |||

| Labor | 25,296.96 | |||

| Tools and supplies | 3,531.12 | |||

| Changing M. of W. equipment | 813.13 | |||

| Switches | 571.67 | |||

| Spikes | 8,508.22 | |||

| Total track | $38,721,10 | 64.80 | ||

| Total | $114,445.75 | |||

| Total average cost per mile | $191.53 | |||

And the superintendent of the S.F. & W. R.R. has also furnished the expenses for that road:

| No. | Average Cost. | |

|---|---|---|

| Engines and tenders | 75 | $76.31 |

| Cars (passenger) | 95 | 4.67 |

| Cars (freight) | 1,133 | 3.88 |

| Track, including sidings | 601.76 | 44.49 |

Nothing was said about shop or other tools, storage tracks, or changing of maintenance of way equipment.

COMPARATIVE STATEMENT OF AVERAGE COST OF LABOR OF VARIOUS ITEMS OF WORK.

| M. & O. R.R. | L. & N. R.R. | E.T.,V. & G. R.R. | Average | |

| Engines and tenders. | $170.88 | Not divided | $45.71 | $108.29 |

| Pass., bag., and ex cars | 7.97 | 4.38 | 6.17 | |

| Freight cars | 3.89 | 3.36 | 3.62 | |

| M. of W. cars | 9.98 | 4.64 | 7.31 | |

| Miles track (including sidings, bridges, etc.) | 32.57 | $34.31 | 19.26 | 28.71 |

| Track tools, per mile | .30 | Not divided | .13 | .21 |

| Temporary tracks | 162.03 | 265.40 | 213.71 | |

| Total per mile of track | $70.38 | Not divided | $44.72 | $57.55 |

COMPARATIVE STATEMENT OF AVERAGE COST OF MATERIAL OF VARIOUS ITEMS OF WORK.

| M. & O. R.R. | L. & N. R.R. | E.T., V.& G. R.R. | Average | |

|---|---|---|---|---|

| Engines and tenders. | $154.82 | Not divided | $16.11 | $85.46 |

| Pass., bag., and ex cars | 1.90 | .35 | 1.12 | |

| Freight cars | .51 | .24 | .37 | |

| M. of W. cars | 3.34 | 1.25 | 2.30 | |

| Miles track (including sidings, bridges, etc.) | 12.80 | $13.02 | 26.88 | 17.55 |

| Track tools, per mile | 2.40 | Not divided | 1.67 | 2.03 |

| Temporary tracks | 162.03 | 40.04 | 101.03 | |

| Total per mile of track | $43.30 | Not divided | $34.34 | $38.82 |

SUMMARY OF STATEMENTS OF L.&N. AND E.T., V.&G. RAILWAYS.

| The mileage changed of the L&N. and E.T., V.& G. systems combined aggregates | 3,622 miles. |

| The total cost of these two roads. | $331,492.59 |

| Or an average per mile of | 91.52 |

| Total miles changed was about | 14,500 miles. |

| Which would give total cost, at same rate. | $1,327,040 |

We should really add to this a large sum for the great number of new locomotives which were purchased to replace old ones, that could not be changed, except at large cost, and which, when done, would have been light and undesirable.

Upon the basis of the work done upon the L. & N. and E.T., V. & G. systems, which, combined, cover about one-fourth the mileage changed, we have made the following estimates, which will, perhaps, convey a better idea of the extent of the work than can be obtained in any other way:

| Miles of track changed, about | 14,500 |

| Locomotives changed, about | 1,800 |

| Cars (pass, and freight) changed, about | 45,000 |

| New axles used, about | 9,000 |

| New wheels used, about | 20,000 |

| Axles turned back, about | 75,000 |

| Wheels pressed on without turning axles, about | 220,000 |

| New brasses used, about | 90,000 |

| Kegs of spikes used, about | 50,000 |

| Cost of material used, about | $600,000 |

| Cost of labor, about | 730,000 |

| Total cost of work, about | 1,330,000 |

| Amount expended on equipment, about | 650,000 |

| Amount expended on track, about | 680,000 |

| Amount expended on track on day of change in labor, about | 140,000 |

The work was done economically, and so quietly that the public hardly realized it was in progress. To the casual observer it was an every day transaction. It was, however, a work of great magnitude, requiring much thought and mechanical ability.

That it was ably handled is evidenced by the uniform success attained, the prompt changing at the agreed time, and the trifling inconvenience to the public.—Jour. Assn. Engineering Societies.

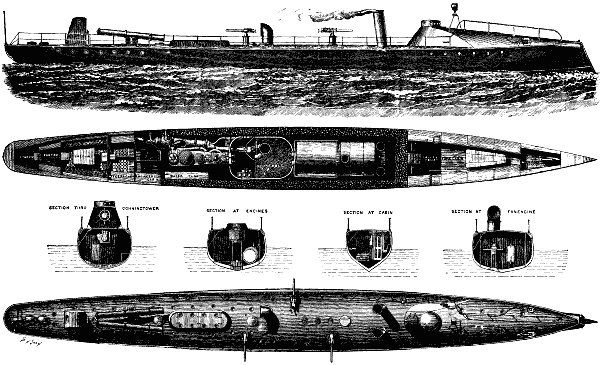

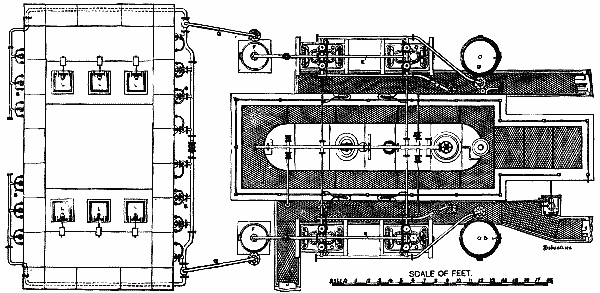

In our present issue, on page 9948, we give illustrations of two torpedo boats, the Azor and Halcon, which have lately been constructed by Messrs Yarrow & Co., of Poplar, for the Spanish government. They are 135 ft. in length by 14 ft. beam, being of the same dimensions as No. 80 torpedo boat, lately completed by the above firm for the Admiralty, which is the largest and fastest torpedo-boat in the British navy.

TORPEDO BOATS FOR THE SPANISH GOVERNMENT.

The general arrangement of these torpedo boats is sufficiently clear from the illustrations to need but little description. Suffice it to say that the engines are of the triple compound type, capable of indicating 1,550 horse power, steam being supplied by one large locomotive boiler, which our readers are already aware is in accordance with the usual practice of the makers, as, by using a single boiler, great simplification of the machinery takes place, and considerably less room is occupied than if two boilers were adopted. It is worthy of record that although in some torpedo boats, and indeed in a great number of them, trouble has been found with the locomotive type of boiler, still we have no hesitation in saying that this is due either to defective design or bad workmanship, and that, if properly designed and constructed, such difficulty does not occur. And it is a fact that Messrs. Yarrow & Co. have already constructed a great number of locomotive boilers of the exceptional size adopted in these two Spanish boats, and they have turned out in every respect, after actual service, perfectly satisfactory.

The forward part of the boat is provided with two torpedo-ejecting tubes, as usual, and near the stern, on deck, it is proposed to place turntables, with two torpedo guns for firing over the sides, as already adopted by several governments. The trials of the Azor took place about two months since, giving a speed during a run of two hours and three quarters, carrying a load of 17 tons, of 24 knots (over 27½ miles) per hour. Since her trial she has steamed out to Spain, having encountered, during a portion of the voyage very bad weather, when her sea going qualities were found to be admirable.

The Halcon, whose official trials took place lately, obtained a speed of 23.5 knots, carrying a load of 17 tons. It may be remarked that a speed of 24 knots, in a boat only 135 ft in length, under the Spanish conditions of trial, is by far the best result that has ever been obtained in a vessel of these dimensions There is, however, no doubt that had the length of the boat been greater, a still higher speed would have been obtained But it was desired by the authorities to keep within the smallest possible dimensions, so as to expose as little area as practicable to the fire of the enemy, it being clearly evident that this is a consideration of the first importance in an unprotected war vessel.

In conclusion, we would add that the hulls of these two Spanish boats are of much greater strength of construction than is usually adopted in torpedo boats, it having been found that for the sake of obtaining exceptional speeds, strength sufficient for actual service has often been injudiciously sacrificed And, judging from the numerous accidents which took place at the recent trials off Portland, we have no doubt that in the future naval authorities will be quite ready and willing to sacrifice a little speed so as to obtain vessels which are more trustworthy. The necessity for this, we feel convinced, will be conclusively shown if ever torpedo boats are engaged in actual warfare, and this not only as regards strength of hull, but also as regards the machinery, which at present is only capable of being handled successfully by men of exceptional training, who in times of war would not be readily procured—The Engineer.

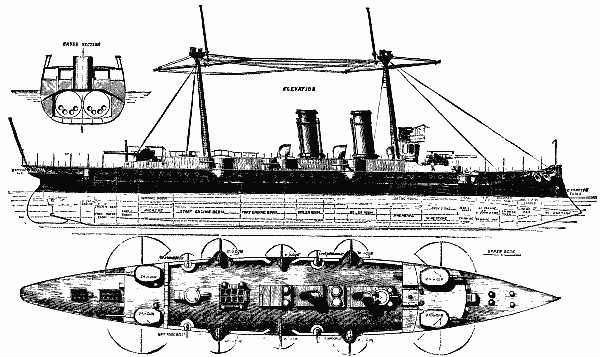

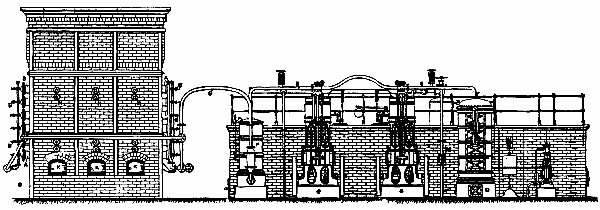

In our SUPPLEMENT, No. 620 we gave an illustration of this ship, with some particulars. The interest expressed in naval circles for further information induces us to give still further engravings of this remarkable vessel, with additional information, for which we are indebted to the Engineer.

THE NEW SPANISH WAR SHIP REINA REGENTE.

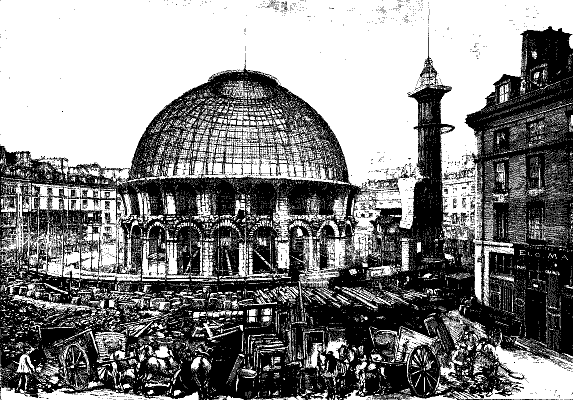

We gave recently a short account of two of the trials of this vessel, and we are, by the courtesy of the builders—Messrs. Thomson, of Clydebank—enabled to lay further particulars before our readers this week. We give herewith engravings of the vessel, which will illustrate her salient points. The principal dimensions are as follows.

Length on water line, 317 ft., breadth, 50 ft. 7 in., depth moulded, 32 ft. 6 in., normal displacement, 4,800 tons, deep load displacement, 5,600* tons. We have before informed our readers that this vessel was designed by Messrs. Thomson, in competition with several other shipbuilding firms of this and other countries, in reply to an invitation of the Spanish government for a cruiser of the first class. The design submitted by the builders of the Reina Regente was accepted, and the vessel was contracted to be built in June of last year. The principal conditions of the contract were as follows.

The ship to steam at a speed of 20½ knots for four runs on the mile and for two hours continuously afterward. She was further to be capable of steaming for six hours continuously at a speed of 18½ knots, without any artificial means of producing draught. She was also to be capable of steaming a distance of at least 5,700 knots for 500 tons of coal, at some speed over 10 knots, to be chosen by the builders. Over the length of her machinery and magazine spaces she was to have a sloping deck extending to 6 ft. below the water line at the side, and formed of plates 4¾ in. thick. This deck was to extend to about 1 ft. above the water line, and the flat part to be 3-1/8 in. thick. Beyond the machinery and magazine spaces, the deck was to be gradually reduced to 3 in. thick at the ends. This deck is intended to protect the vitals of the ship, such as boilers, engines, powder magazines, steering gear, etc., from the effects of shot and shell, but the floating and stability maintaining power of the ship was to be dependent upon a similar structure raised above this protective deck to a height of about 5 ft. above the water.

This structure is covered by a water tight deck known as the main deck of the ship, on which the cabins and living spaces are arranged. The space between the main and protective deck is divided, as may be seen by reference to the protective deck plan, into many strong, water tight spaces, most of which are not more than about 500 cubic feet capacity. The spaces next to the ship's side are principally coal bunkers, and may, therefore, exclude largely any water that should enter. The first line of defense is formed inside these coal bunkers by a complete girdle of coffer dams, which can be worked from the main deck. These it is intended to fill with water and cellulose material, and as they are also minutely subdivided, the effects of damage by shot and consequent flooding may be localized to a considerable extent. The guns of the ship are to consist of four 20 centimeter Hontorio breech loading guns on Vavasseur carriages, six 12 centimeter guns, eight 6 pounder rapid firing, and eight or ten small guns for boats and mitrailleuse purposes, four of which are in the crow's nests at the top of the two masts of the ship. We may remark in passing that the builders saw their way at an early period of the construction to suggest an addition to the weight of the large sized guns, and there will actually be on the ship four 24 centimeter guns, instead of four 20 centimeter. The vessel was to carry five torpedo tubes, two forward in the bow, one in each broadside, and one aft. All these tubes to be fixed. To fulfill the speed condition, four boilers were necessary and two sets of triple expansion engines, capable of developing in all 12,000 horse power.

Now that the vessel has been completely tried, the promises by the builders may be compared with the results determined by the commission of Spanish officers appointed by the government of Spain to say whether the vessel fulfilled in all respects the conditions laid down in the contract. The mean speed attained for the two hours' run was 20.6 knots, as compared with 20.5 guaranteed, but this speed was obtained with 11,500 horse power instead of the 12,000 which the machinery is capable of developing. The officers of the Spanish commission were anxious not to have the vessel's machinery pressed beyond what was necessary to fulfill the speed conditions of the contract; but they saw enough to warrant them in expressing their belief that the vessel can easily do twenty-one knots when required, and she actually did this for some time during the trial.

During the natural draught trial the vessel obtained a mean speed of 18.68 knots, on an average of 94¾ revolutions—the forced draught having been done on an average of 105½ revolutions. The consumption trial, which lasted twelve hours, was made to determine the radius of action, when the ship showed that at a speed of 11.6 knots she could steam a distance of 5,900 knots. Further trials took place to test the evolutionary powers of the vessel, though these trials were not specified in the contract.

The vessel, as may be seen from the engravings, is fitted with a rudder of a new type, known as Thomson & Biles' rudder, with which it is claimed that all the advantage of a balanced rudder is obtained, while the ship loses the length due to the adoption of such a rudder. It is formed in the shape of the hull of the vessel, and as the partial balance of the lower foreside gradually reduces the strains, the rudder head may be made of very great service. As a matter of fact, this rudder is 230 ft. in area, and is probably the largest rudder fitted to a warship. The efficiency of it was shown in the turning trials, by its being able to bring the vessel round, when going at about nineteen knots, in half a circle in one minute twenty-three seconds, and a complete circle in two minutes fifty-eight seconds, the diameter of the circle being 350 yards. This result, we believe, is unrivaled, and makes this vessel equal in turning capabilities to many recent warships not much more than half her length.